Skill game, tennis (V8348-00)

Product reviews

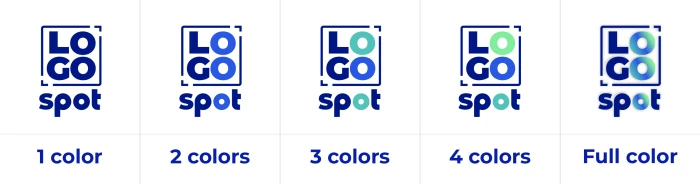

Color variants

neutral

neutral

Product description

Parameters

Marking method

Thermal transfer1 up to 200 cm²

A printing method that involves thermally welding a pre-prepared FLEX or FLOCK foil, cut on a plotter into the shape of the desired emblem or logo, into the material. No tonal transitions or photos are possible; it only works on specific shapes and colours. Files must be prepared in vectors.

Thermal transfer2 from 200 cm²

A printing method that involves thermally welding a pre-prepared FLEX or FLOCK foil, cut on a plotter into the shape of the desired emblem or logo, into the material. No tonal transitions or photos are possible; it only works on specific shapes and colours. Files must be prepared in vectors.

DTF1 up to 100 cm²

Direct To Film - technology of thermal transfer prints in FULL COLOUR with tonal transitions. It is possible to produce graphics of any shape, in high quality and with vivid colours.

DTF2 from 101 to 200 cm²

Direct To Film - technology of thermal transfer prints in FULL COLOUR with tonal transitions. It is possible to produce graphics of any shape, in high quality and with vivid colours.

DTF3 from 201 to 400 cm²

Direct To Film - technology of thermal transfer prints in FULL COLOUR with tonal transitions. It is possible to produce graphics of any shape, in high quality and with vivid colours.

Screenprint0

Screen printing involves applying ink to a product using a mesh with small holes through which it passes onto the surface to be marked. In this way, one colour is printed.

For multi-colour logos, several screens are used.

Screenprint2

Screen printing involves applying ink to a product using a mesh with small holes through which it passes onto the surface to be marked. In this way, one colour is printed.

For multi-colour logos, several screens are used.

Laser3A up to 20 cm²

Laserengraving involves permanently burning any logo, lettering or shape onto the surface of an object using a laser. It is always one colour, depending on the material on which we perform the engraving. The design should be made in vectors.

Laser3B up to 60 cm²

Laserengraving involves permanently burning any logo, lettering or shape onto the surface of an object using a laser. It is always one colour, depending on the material on which we perform the engraving. The design should be made in vectors.

Laser3C from 60 cm²

Laserengraving involves permanently burning any logo, lettering or shape onto the surface of an object using a laser. It is always one colour, depending on the material on which we perform the engraving. The design should be made in vectors.

Full colour UV1 print up to 10 cm²

Full colour UV printing involves printing in full colour on a variety of substrates, at a high resolution of 1440 x 1200 dpi, with UV-curable inks (CMYK + white). Files can be vector or bitmap. Unlike most methods, it offers the possibility to print tonal transitions.

Full colour UV2 print up to 30 cm²

Full colour UV printing involves printing in full colour on a variety of substrates, at a high resolution of 1440 x 1200 dpi, with UV-curable inks (CMYK + white). Files can be vector or bitmap. Unlike most methods, it offers the possibility to print tonal transitions.

Full colour UV3 print up to 100 cm²

Full colour UV printing involves printing in full colour on a variety of substrates, at a high resolution of 1440 x 1200 dpi, with UV-curable inks (CMYK + white). Files can be vector or bitmap. Unlike most methods, it offers the possibility to print tonal transitions.

Laser2A

Laserengraving involves permanently burning any logo, lettering or shape onto the surface of an object using a laser. It is always one colour, depending on the material on which we perform the engraving. The design should be made in vectors.

Laser2B up to 60 cm²

Laserengraving involves permanently burning any logo, lettering or shape onto the surface of an object using a laser. It is always one colour, depending on the material on which we perform the engraving. The design should be made in vectors.

Add a review